Head Porting- Milling (CNC)

- saxophonias

- Posts: 2593

- Joined: Fri Jul 03, 2009 6:03 am

Head Porting- Milling (CNC)

This is a common procedure to increase volumetric efficiency and the air flow of our head. Still we should look after how much we are going to mill /port the head and to pick a precise piece of machinery for this job, as the results will be catastrophic if the job isn't done properly.

At this topic we are going to describe the procedure with videos and will give examples of d14 head jobs.

At this topic we are going to describe the procedure with videos and will give examples of d14 head jobs.

Re: Head Porting- Milling (CNC)

is there advantage on this procedure over the entire replacement for a D16's head? Best Regards

-

henrique b correia

- Posts: 29

- Joined: Sun Aug 09, 2009 8:45 pm

- Location: portugal

Re: Head Porting- Milling (CNC)

nice. i'm also interested in this...

- saxophonias

- Posts: 2593

- Joined: Fri Jul 03, 2009 6:03 am

Re: Head Porting- Milling (CNC)

There is always benefit in this procedure as stock heads aren't perfect in terms of flow. Still as i said earlier you shouldn't trust anyone to do this. There have to be precision pieces of machinery and be experienced as there are plenty of techniques.Law_ wrote:is there advantage on this procedure over the entire replacement for a D16's head? Best Regards

I'll make another topic to compare heads (vtec non vtec) and whether it is worth performing the mini-me over camming your non vtec head. This isn't an easy answer

-

hondaNickx

- Posts: 713

- Joined: Wed Aug 05, 2009 1:06 am

- Location: Belgium

The Magical Myth of Flowbench - Porting.(by 'The Motoman')

Food for the brain!

Copied from the original Motoman Article

The Magical Myth of Flowbench - Porting

Once upon a time...

The flowbench is a machine that measures the airflow through the ports by sucking air thru like a vacuum cleaner. The vacuum gauges on the bench actually measure the resistance to the flow thru the ports, and the result is converted into CFM. That means "how many Cubic Feet of air will flow through the port per Minute."

Anyone who buys a flowbench and a dremel tool is "qualified" to flowbench - port heads. The Superflow flowbench owner's manual says that:

" For every 1 CFM of increase in intake flow,

you'll gain .43 horsepower. "

If you want more water to flow through a pipe, just make the pipe bigger.

There's something wrong with this though.

It's easy to understand why so many people automatically think Flowbench - Porting, or "more is better" is a way to improve power.Without closer examination, it seems quite logical.

In the last issue of Power News you learned to think of a four stroke engine in a whole new way... 8 Phases !!

In the 8 phase engine article, you'll remember that the intake "stroke" actually consists of 3 phases.( Overlap, Suction and Charging.)

3 INTAKE PHASES

There are 3 distinctly different ways the intake charge enters the engine.

Intake Overlap:

The intake phase actually begins during the end of the exhaust return phase. About 15 degrees before the top of the piston stroke, the intake valves open. This is also called the camshaft overlap period because the intake and exhaust valves are both open a small amount at the same time. (the exhaust valves are closing and the intake valves are opening.)

The low pressure from the exiting exhaust creates a flow pattern across the top of the cylinder that draws fresh intake mixture into the cylinder to displace the last remaining spent gases. The truly ingenious part of this design, is that the flow of intake mixture into the cylinder has been started while the piston is still going up... against the direction of the flow it's pumping !!!

Intake Suction:

Now the piston has passed the top and now accelerating down it's stroke. At the same time, the valves are opening rapidly to allow the intake charge to enter the cylinder with minimal resistance. Since the fuel/air mixture has a certain amount of mass, it tends to lag behind the piston, and this lag time becomes more pronounced as the RPM's increase. As a result, the piston first creates a low pressure condition in the cylinder, and the mixture rushes in to fill it.

Intake Charging:

This is the time when the piston has passed the bottom of it's stroke, and begun to move up. Because of the charge momentum created by the intake suction phase, lots of fuel and air mixture is still rushing down the intake tract to fill the cylinder. This phenomenon increases with the engine speed, to the point that a progressively higher percentage of the cylinder filling occurs after the piston is no longer physically "sucking" the charge in. Because of this, it's necessary to extend the intake phase way past the physical 180 degree intake stroke. On average, the valves don’t completely close until the piston has moved up about 55 degrees past the bottom of it's 180 degree stroke !!

Uh - Oh ...

It turns out that a flowbench measures the least important aspect of intake cycle efficiency !!It's true !! When you stop to think about it, a flowbench only measures the efficiency of the "suction phase".

That's not the right thing to measure?!

Why ?? Because, it doesn't matter how well the cylinder is filled at that point in the intake cycle !

What ... that sounds crazy !!!

It's 100% true ... it's simply a matter of the sequence of events ! The success of the last event, the charging phase, determines the success of the entire intake process.

What happens when a low velocity port fills the cylinder really well, but too early ?? The result is a slower intake charge that stops flowing into the cylinder. Then some of the charge gets pushed back out of the cylinder and into the port as the piston returns up the bore during the intake charging phase. The gain in flow doesn't offset the loss in port velocity.

Here's an analogy:

It's just like a roadrace; you can lead for 3 laps, then run out of steam and end up in 7th place.

In racing, only the last lap counts, because the one who leads at the checkered flag wins.In the intake cycle "race" the last lap is the charging phase, and the checkered flag is the intake valves closing.

So in the final result, the first 2 phases don't matter if the 3rd phase is unsuccessful !! The total intake volume that will be burned is determined by the amount that remains in the cylinders after the intake valves close. That means that an early gain during the suction phase can be easily lost during the charging phase. And, if the intake charge returns back into the port during the piston's upstroke, the result is going to be a net loss !!

It gets worse !

On a carbureted bike the reversing charge will create an effect called double carburetion, which means the mixture will become even richer with fuel as it passes back over the main jet nozzle for a second time.

Have we lost enough power yet ??

Wait... it gets even worse !!

Here's a real "out of the box" idea: high flow ports also flow really well backwards !!! All that work on the flowbench comes back to haunt you when the piston now has even less resistance to pushing the intake charge back into the " high flowing port " !!!!!!! When you begin to consider the consequences of all this, the whole idea of "more flow is better" comes crashing down like a lead balloon.

What's The Secret ??

Using the race analogy, if you increase the Port Velocity, by making the port smaller, the intake cycle "race" starts out slower, gains momentum and makes a tremendous charge on the "last lap" to overtake the high flow port and win the "race". The interesting thing is, this type of port will always lose in a flowbench contest !!!

Remember:

More Flow Doesn't Always Equal More Power !!

But Less Velocity Usually Equals Less Power !!!

Copied from the original Motoman Article

The Magical Myth of Flowbench - Porting

Once upon a time...

The flowbench is a machine that measures the airflow through the ports by sucking air thru like a vacuum cleaner. The vacuum gauges on the bench actually measure the resistance to the flow thru the ports, and the result is converted into CFM. That means "how many Cubic Feet of air will flow through the port per Minute."

Anyone who buys a flowbench and a dremel tool is "qualified" to flowbench - port heads. The Superflow flowbench owner's manual says that:

" For every 1 CFM of increase in intake flow,

you'll gain .43 horsepower. "

If you want more water to flow through a pipe, just make the pipe bigger.

There's something wrong with this though.

It's easy to understand why so many people automatically think Flowbench - Porting, or "more is better" is a way to improve power.Without closer examination, it seems quite logical.

In the last issue of Power News you learned to think of a four stroke engine in a whole new way... 8 Phases !!

In the 8 phase engine article, you'll remember that the intake "stroke" actually consists of 3 phases.( Overlap, Suction and Charging.)

3 INTAKE PHASES

There are 3 distinctly different ways the intake charge enters the engine.

Intake Overlap:

The intake phase actually begins during the end of the exhaust return phase. About 15 degrees before the top of the piston stroke, the intake valves open. This is also called the camshaft overlap period because the intake and exhaust valves are both open a small amount at the same time. (the exhaust valves are closing and the intake valves are opening.)

The low pressure from the exiting exhaust creates a flow pattern across the top of the cylinder that draws fresh intake mixture into the cylinder to displace the last remaining spent gases. The truly ingenious part of this design, is that the flow of intake mixture into the cylinder has been started while the piston is still going up... against the direction of the flow it's pumping !!!

Intake Suction:

Now the piston has passed the top and now accelerating down it's stroke. At the same time, the valves are opening rapidly to allow the intake charge to enter the cylinder with minimal resistance. Since the fuel/air mixture has a certain amount of mass, it tends to lag behind the piston, and this lag time becomes more pronounced as the RPM's increase. As a result, the piston first creates a low pressure condition in the cylinder, and the mixture rushes in to fill it.

Intake Charging:

This is the time when the piston has passed the bottom of it's stroke, and begun to move up. Because of the charge momentum created by the intake suction phase, lots of fuel and air mixture is still rushing down the intake tract to fill the cylinder. This phenomenon increases with the engine speed, to the point that a progressively higher percentage of the cylinder filling occurs after the piston is no longer physically "sucking" the charge in. Because of this, it's necessary to extend the intake phase way past the physical 180 degree intake stroke. On average, the valves don’t completely close until the piston has moved up about 55 degrees past the bottom of it's 180 degree stroke !!

Uh - Oh ...

It turns out that a flowbench measures the least important aspect of intake cycle efficiency !!It's true !! When you stop to think about it, a flowbench only measures the efficiency of the "suction phase".

That's not the right thing to measure?!

Why ?? Because, it doesn't matter how well the cylinder is filled at that point in the intake cycle !

What ... that sounds crazy !!!

It's 100% true ... it's simply a matter of the sequence of events ! The success of the last event, the charging phase, determines the success of the entire intake process.

What happens when a low velocity port fills the cylinder really well, but too early ?? The result is a slower intake charge that stops flowing into the cylinder. Then some of the charge gets pushed back out of the cylinder and into the port as the piston returns up the bore during the intake charging phase. The gain in flow doesn't offset the loss in port velocity.

Here's an analogy:

It's just like a roadrace; you can lead for 3 laps, then run out of steam and end up in 7th place.

In racing, only the last lap counts, because the one who leads at the checkered flag wins.In the intake cycle "race" the last lap is the charging phase, and the checkered flag is the intake valves closing.

So in the final result, the first 2 phases don't matter if the 3rd phase is unsuccessful !! The total intake volume that will be burned is determined by the amount that remains in the cylinders after the intake valves close. That means that an early gain during the suction phase can be easily lost during the charging phase. And, if the intake charge returns back into the port during the piston's upstroke, the result is going to be a net loss !!

It gets worse !

On a carbureted bike the reversing charge will create an effect called double carburetion, which means the mixture will become even richer with fuel as it passes back over the main jet nozzle for a second time.

Have we lost enough power yet ??

Wait... it gets even worse !!

Here's a real "out of the box" idea: high flow ports also flow really well backwards !!! All that work on the flowbench comes back to haunt you when the piston now has even less resistance to pushing the intake charge back into the " high flowing port " !!!!!!! When you begin to consider the consequences of all this, the whole idea of "more flow is better" comes crashing down like a lead balloon.

What's The Secret ??

Using the race analogy, if you increase the Port Velocity, by making the port smaller, the intake cycle "race" starts out slower, gains momentum and makes a tremendous charge on the "last lap" to overtake the high flow port and win the "race". The interesting thing is, this type of port will always lose in a flowbench contest !!!

Remember:

More Flow Doesn't Always Equal More Power !!

But Less Velocity Usually Equals Less Power !!!

Quote from Endyn:"The combustion chamber is a better shape than the DOHC.So don't chunk those 1.6 SOHC engines, they can make really good power. For a pure performance application, regardless of application, I'd choose the SOHC. No bull!"

-

hondaNickx

- Posts: 713

- Joined: Wed Aug 05, 2009 1:06 am

- Location: Belgium

Re: The Magical Myth of Flowbench - Porting.(by 'The Motoman')

And more

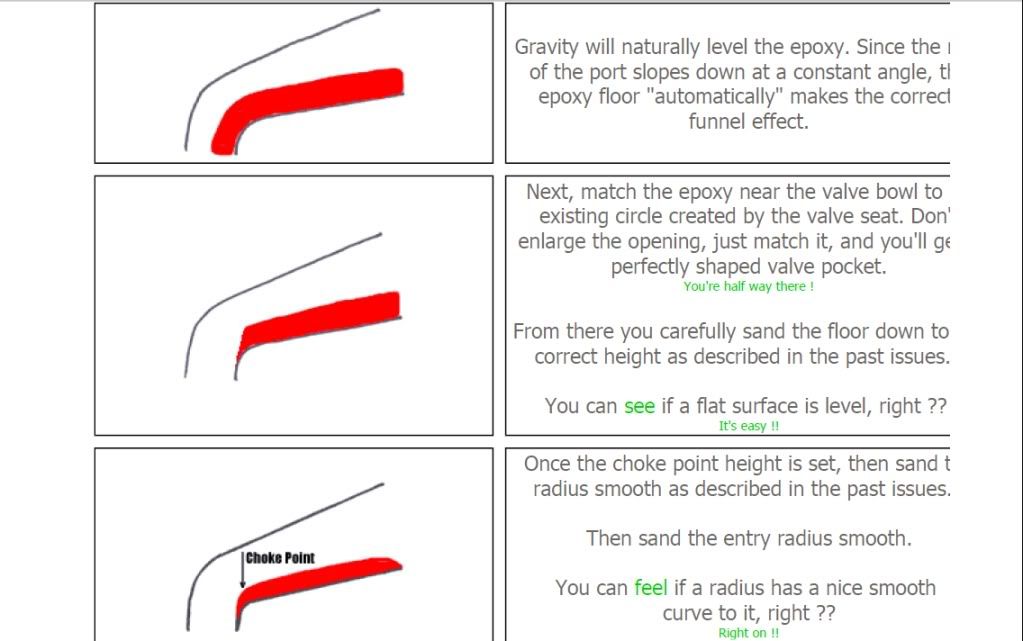

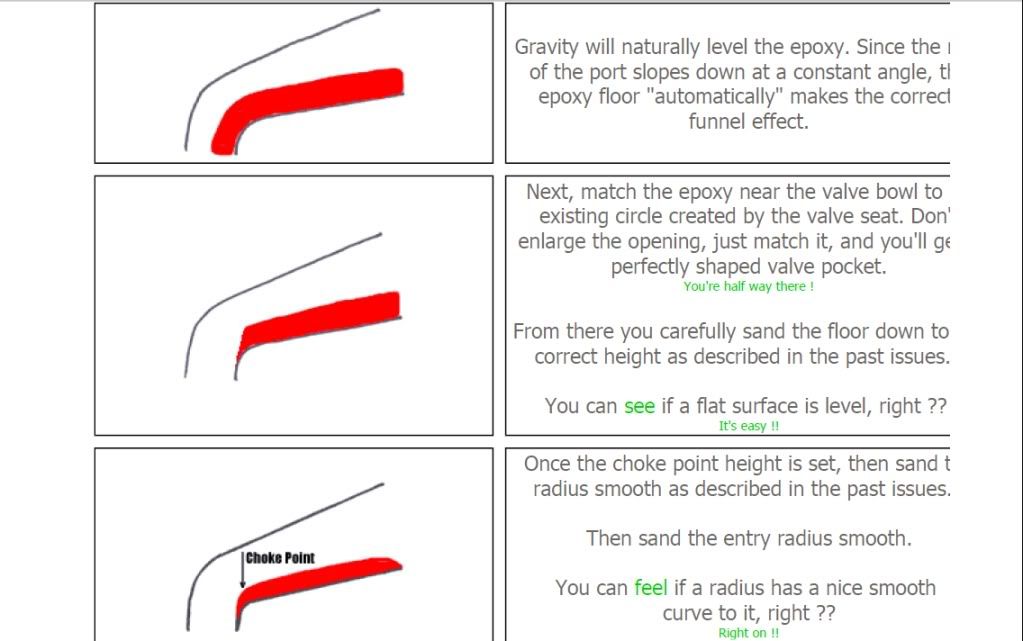

This is how Motoman does it

If you own a flowbench:

It's tempting to want to increase the port flow, but it much more important to increase the velocity !!Most modern engines already have more than enough flow in the stock ports. What they need is more velocity. I've intentionally made the ports so small that they flowed 8% less than the stock ports. These high velocity ports always make the best midrange and top end power !! Do the "clay test" first !!

Never Fear Failure

If a port can be made smaller without losing flow, then it seems logical that there should be a midrange gain, and you can consider that knowledge a win. On the other hand, if the bike turn out to be slow, it could be embarrassing !! But it wouldn't be failure, because it you'd learn a ne

way that didn't work, and that knowledge is a win as well !! Either way... you win !!

Here are all the links to motoman's powernews.You can see how you need to do everything.

http://www.hunterdogs.org/GeneralInfo/A ... lyWork.pdf

http://www.hunterdogs.org/GeneralInfo/A ... orting.pdf

http://www.hunterdogs.org/GeneralInfo/A ... mework.pdf

http://www.hunterdogs.org/GeneralInfo/A ... erbike.pdf

http://www.hunterdogs.org/GeneralInfo/A ... nozzle.pdf

http://www.hunterdogs.org/GeneralInfo/A ... tories.pdf

Even a succes story from the Netherlands

"Hey Moto Man .... It Works in Netherlands !

This is LEMSTRA RACING in Netherlands. We have tuned

two Kawasaki ZX6R's with, 01 works racing kit,

adjustable ignition (mapping per 250 revs), and we

tuned one with ports like you described at 65% smaller

and we went from 110 rear wheel bhp to 115.6!

Thanks and greetings from Alkmaar, Holland !

~ Freek (Netherlands)"

I actually know a guy who has applied this technique to his d15b2 head.

He gained 13Cfm in flow and the response of the engine is insane !

This is how Motoman does it

If you own a flowbench:

It's tempting to want to increase the port flow, but it much more important to increase the velocity !!Most modern engines already have more than enough flow in the stock ports. What they need is more velocity. I've intentionally made the ports so small that they flowed 8% less than the stock ports. These high velocity ports always make the best midrange and top end power !! Do the "clay test" first !!

Never Fear Failure

If a port can be made smaller without losing flow, then it seems logical that there should be a midrange gain, and you can consider that knowledge a win. On the other hand, if the bike turn out to be slow, it could be embarrassing !! But it wouldn't be failure, because it you'd learn a ne

way that didn't work, and that knowledge is a win as well !! Either way... you win !!

Here are all the links to motoman's powernews.You can see how you need to do everything.

http://www.hunterdogs.org/GeneralInfo/A ... lyWork.pdf

http://www.hunterdogs.org/GeneralInfo/A ... orting.pdf

http://www.hunterdogs.org/GeneralInfo/A ... mework.pdf

http://www.hunterdogs.org/GeneralInfo/A ... erbike.pdf

http://www.hunterdogs.org/GeneralInfo/A ... nozzle.pdf

http://www.hunterdogs.org/GeneralInfo/A ... tories.pdf

Even a succes story from the Netherlands

"Hey Moto Man .... It Works in Netherlands !

This is LEMSTRA RACING in Netherlands. We have tuned

two Kawasaki ZX6R's with, 01 works racing kit,

adjustable ignition (mapping per 250 revs), and we

tuned one with ports like you described at 65% smaller

and we went from 110 rear wheel bhp to 115.6!

Thanks and greetings from Alkmaar, Holland !

~ Freek (Netherlands)"

I actually know a guy who has applied this technique to his d15b2 head.

He gained 13Cfm in flow and the response of the engine is insane !

Quote from Endyn:"The combustion chamber is a better shape than the DOHC.So don't chunk those 1.6 SOHC engines, they can make really good power. For a pure performance application, regardless of application, I'd choose the SOHC. No bull!"

- saxophonias

- Posts: 2593

- Joined: Fri Jul 03, 2009 6:03 am

Re: The Magical Myth of Flowbench - Porting.(by 'The Motoman')

Great post. I look into it in detail and get back to it.

Re: The Magical Myth of Flowbench - Porting.(by 'The Motoman')

Great Post ! Thank you very much. Cheers

Re: The Magical Myth of Flowbench - Porting.(by 'The Motoman')

well it seems a good idea. it is for bikes but obviously applies to cars. making the ports smaller (or not making them bigger) seems fine. not to polish the ports or make them rough seems to work too... it is trully controversial but i believe it. I reccommend everyone to read directly from the site as some PDFs have some text loss.

Thank you for sharing hondaNickx i will consider this in future.

How about Intake manifolds?

Endyn are polishing all the inside but IMs just have air ! I guess it will be ok in this case.

Cheers

Thank you for sharing hondaNickx i will consider this in future.

How about Intake manifolds?

Endyn are polishing all the inside but IMs just have air ! I guess it will be ok in this case.

Cheers

- Dodo Bizar

- Site Admin

- Posts: 2011

- Joined: Mon Jun 22, 2009 10:36 pm

Re: The Magical Myth of Flowbench - Porting.(by 'The Motoman')

Very very nice post, good information.