I've seen D14 turbo engines with stock engine holding out on 180 hp at the crank without problems.And a Dodo himself in a N/A version at 8000rpm without problems too.I'm worried myself it's kinda on the limit ,but you can port the stock pump yourself.It's not that difficult to do ,i would just improve flow and not touch the pressure spring it increases allready.I'm going to quote a very good post from "Rushi" from OneCamOnly,he has ported his y8 pump in a very good way .

rushi wrote:

"As I promised, this is a sequel to my

http://onecamonly.com/showthread.php?t=1854 oilpump info thread.

I describe whats wrong with stock oilpump(s) and what I did to my P7A D16Y8 oilpump to perform strong in my new D15 setup. I won't go into cranktrigger stuff this time, its been covered in info thread and others before.

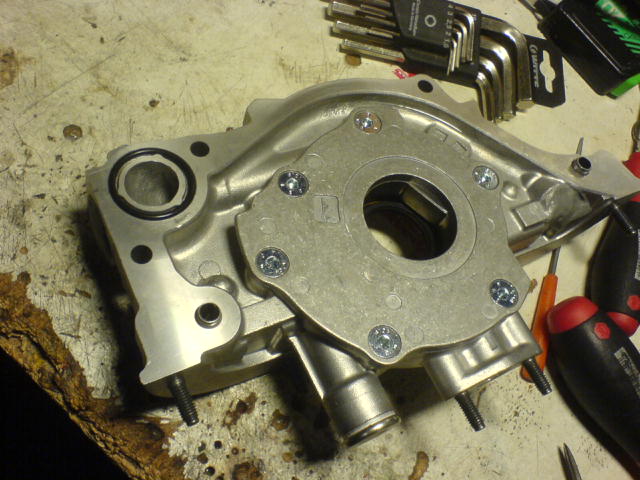

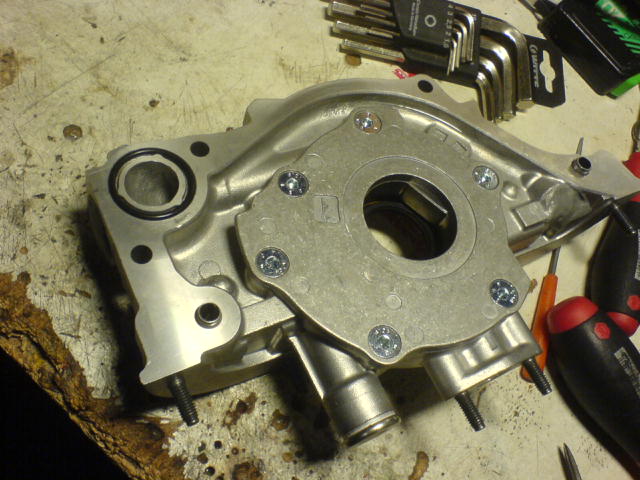

So, lets take a few looks at the stock pump and whats inside it.

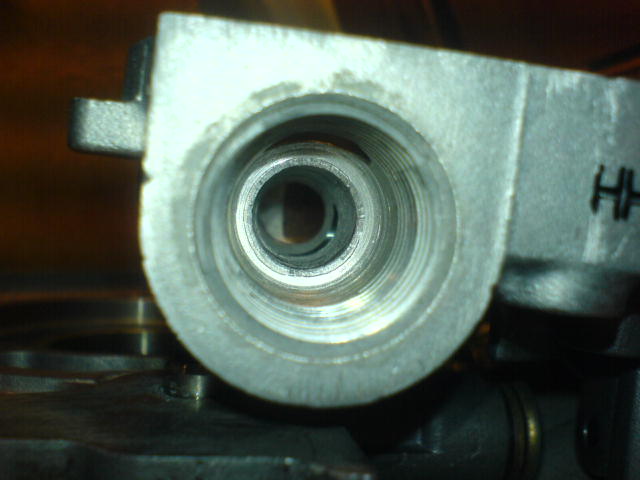

This is not a very good picture, but pretty much the only one I took that describes the problem areas inside the pump. Take a look at the oil exit. There's some very sharp edges and lips where the exit bore meets the rotor chamber. These form some serious resistance to smooth and efficient flow, and should be removed and radiused. Intake port is not well visible, but its only a drilled 14mm hole coming into rotor chamber and has very sharp 90-degree edge around it. Serious radiusing needed here too.

This is how they do look after the needed modifications. I also drilled the intake passage with 15.5mm bit (~16mm bore) and the exit passage with 13mm (~13.5mm bore) to increase the CSA a bit.

Then comes the more serious (and difficult) thing to make better and with my very limited knowledge on pumps, this is the biggest culprit why Y8 pump flows ~25% less than older pumps. The exit from pump housing to block is plain horrible. Passage expands abruptly into much bigger CSA/volume chamber that only has a tiny 12mm hole again with very sharp 90-degree edges. Outlet passage in these pics is already drilled 2mm larger, it was 11.5mm, now 13.5mm.

Here the exit port is grinded close to final shape and Allen plug torqued down with Loctite 243. You can see that I punched a lot of small spots into casting and grinded some "pockets" to get a better bonding and for a mechanical lock for the Devcon I used to fill the port curve.

Here is the "magic stuff" to shape the pump exit, and how it looks after applying it into pump housing. I mixed it way too much, so I also plugged the Allen plug so noone won't ever try to break this up..

At this point with plenty of Devcon mixed up its right time to fill the dipstick hole in Y8 pump housing, since it's going to be used with D15B2 that has dipstick in the block.

Then the final looks about how the pump exit looks when its grinded/sanded into proper shape. I spend a lots of time and effort to shape the exit so it aims the flow as directly into block passage as possible. Tested with pressurized air, and the flow is very nice and straight now. This is what we call efficiency, flow doesn't need to do (much) work to turn into right direction, and this is where the power comes from!

Last thing while assembling the pump, I replaced stock 16mm Phillips-headed screws with 4mm longer Allen-headed ISO 10.9-grade screws. Screw holes are deep enough, but need to be tapped a couple of millimeters deeper. Reason I did this is that Allen-headed screws are MUCH nicer and precise to torque down than Phillips-ones.

Finalized product:

Enjoy. Always use extreme cleanliness when assembling the oilpump and applying Devcon, use proper solvents and follow the Devcon instructions for proper bonding!

This is the oilpump modification upto my best current knowledge. There might be some other internal tricks that could be done, perhaps with Devcon (like shallower tapers inside, similar to stock PLC oilpump) but like I told, I don't know much about pumps (yet). Increasing the pressure with washers/shims under the spring is unnecessary, these mods will already increase the volume flow a lot and with restrictions (bearings and relief valve) staying the same, pressure will be high enough."